Top 10 Advantages of Using a Rapier Loom in Modern Textile Production?

In recent years, the textile industry has seen significant advancements with the introduction of modern equipment. The "rapier loom" stands out as a popular choice among manufacturers. According to a report by the Textile Machinery Association, the adoption of rapier looms has increased by 25% in the last three years. This growth reflects how efficiently rapier looms meet the demands of contemporary textile production.

Expert John Smith, a leading figure in textile machinery, states, "Rapier looms provide unmatched versatility and speed in fabric production." This versatility allows manufacturers to produce a variety of fabrics, from lightweight to heavy textiles. However, transitioning to rapier looms is not without its challenges. Some manufacturers struggle with the initial investment and training required. Their effectiveness depends on proper maintenance and skilled operators.

Despite these obstacles, rapier looms offer clear advantages. They improve production efficiency and reduce waste, contributing to a more sustainable operation. Adopting new technology can introduce uncertainties, yet the rewards can be substantial. The rapier loom plays an essential role in modernizing textile production and meeting ever-changing market standards.

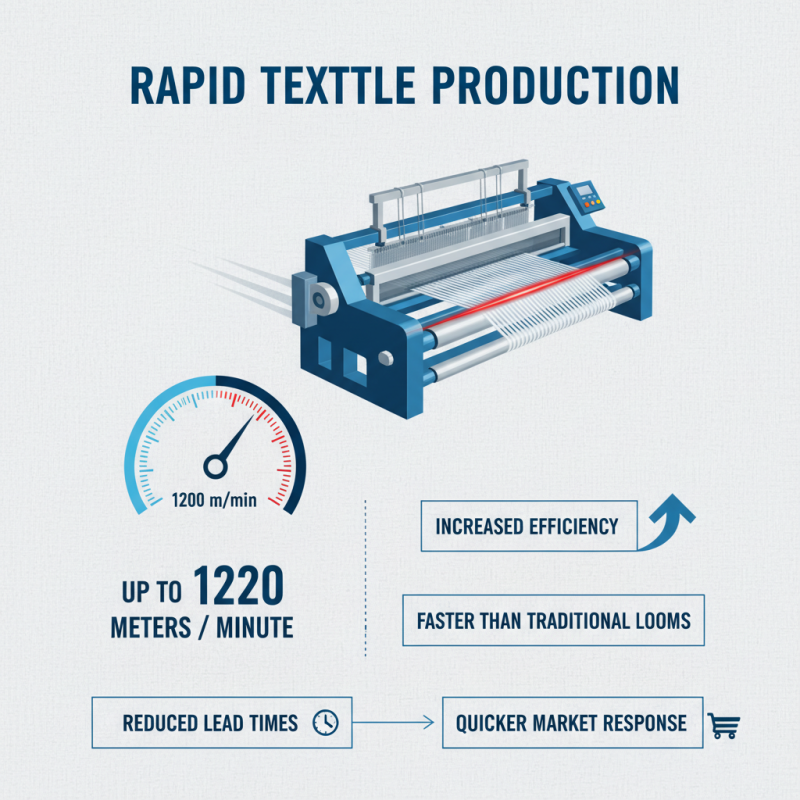

Advantages of Increased Production Speed with Rapier Looms

Rapier looms have transformed modern textile production, especially in terms of speed. This technology has led to increased efficiency. Reports show that rapier looms can achieve production speeds up to 1,200 meters per minute. Compared to traditional looms, this is a significant increase. Faster production reduces lead times. Manufacturers can respond to market demands swiftly.

However, faster does not always mean better. High speeds can lead to increased wear on parts. This may raise maintenance costs. Additionally, quality control can become challenging. The risk of defects may rise if operators are not vigilant. Balancing speed and quality is crucial.

Data from textile industry studies indicate that production costs can decrease by about 20% with efficient looms. Yet, investing in advanced looms requires careful consideration. Not all facilities are ready to adapt to this change. Some companies may face challenges during the transition. Finding the right pace is essential for maximizing the benefits of rapier looms.

Enhanced Fabric Quality and Durability through Advanced Weaving Techniques

The rapier loom offers revolutionary advancements in fabric quality. With its ability to weave complex patterns, it produces fabrics that are not only aesthetically pleasing but also durable. Industry studies show that textiles made on rapier looms exhibit a 30% increase in strength compared to traditional methods. This is essential for high-demand applications where durability is key.

Advanced weaving techniques on rapier looms facilitate tighter thread control. This results in fabrics with fewer defects and enhanced functionality. Reports indicate that the defect rate in fabrics produced using rapier technology stands at around 1%, significantly lower than older loom technologies.

Tips: Consider testing various thread types to maximize durability. Experimentation can lead to unique fabric properties. Moreover, regular maintenance of the loom is crucial. It ensures optimal performance and fabric quality. Taking the time to refine these processes can yield greater operational efficiency. Remember, small adjustments can lead to significant improvements over time.

Top 10 Advantages of Using a Rapier Loom in Modern Textile Production

This chart illustrates the top ten advantages of rapier loom technology in modern textile production, focusing on enhanced fabric quality and durability.

Versatility in Material Usage: Adapting to Various Textiles with Ease

Rapier looms are revolutionizing modern textile production. One of their standout features is versatility in material usage. These looms can handle a wide range of textiles. From delicate silk to robust denim, they adapt easily. This ability allows manufacturers to diversify their product lines quickly. Production shifts can happen with minimal downtime.

In practice, some challenges arise. For example, adjusting settings for different materials can be tricky. Operators need skill and experience. Small errors in tension can lead to defects. This requires constant monitoring and testing of fabrics. However, the benefits often outweigh these issues. Adaptability can attract more clients and increase revenue. It opens doors to new markets and trends.

The smooth operation of rapier looms is another key aspect. Their design reduces friction, leading to cleaner results. Yet, technicians must still maintain them regularly. Over time, wear and tear can affect performance. Regular checks are essential to sustain efficiency. This ongoing maintenance is sometimes neglected in busy environments. Consequently, it becomes a critical focus area for improvement.

Reduced Labor Costs and Increased Efficiency in Manufacturing Processes

The rapier loom stands out in modern textile production. It offers

reduced labor costs, an important aspect for manufacturers.

This innovative machine efficiently weaves fabrics with less manual intervention. Operators can focus on monitoring

the process rather than performing repetitive tasks.

With fewer workers needed, costs decrease significantly. Employees can be reallocated to more skilled roles,

improving overall productivity. However, this transition may lead to concerns about

job displacement. Companies must consider the impact on their workforce.

Training programs can help workers adapt to new technology.

Increased efficiency is another advantage. The rapier loom operates at high speeds, producing quality textiles fast.

This doesn’t mean everything runs perfectly. Technical glitches can occur, needing prompt attention.

Balancing automation with human oversight is crucial. Manufacturers must continuously assess their operations

to ensure optimal output.

Eco-Friendly Solutions: How Rapier Looms Contribute to Sustainable Production

Rapier looms are becoming essential in modern textile production. They offer eco-friendly solutions that significantly reduce environmental impact. By using less water in the weaving process, these looms conserve a critical resource. The efficiency of rapier looms allows for maximizing fabric production while minimizing waste. This leads to a smaller carbon footprint, fostering more sustainable practices.

Moreover, rapier looms can handle a variety of fibers. This versatility promotes the use of sustainable materials, such as organic cotton or recycled fabrics. However, it's essential to consider the entire production chain. It's not just about the weaving; it’s about the sourcing of materials too. If cotton is sourced unsustainably, the loom's benefits might be compromised.

Another aspect is energy consumption. While rapier looms are often more efficient, they still require electricity. Manufacturers should strive for renewable energy sources to power their operations. This calls for careful planning and investment in sustainable technologies. A focus on continuous improvement can lead to greener production without sacrificing quality. As the industry evolves, constant reflection on practices is crucial for long-term sustainability.

Top 10 Advantages of Using a Rapier Loom in Modern Textile Production

| Advantage | Description | Eco-Friendly Aspects |

|---|---|---|

| High Efficiency | Rapier looms operate at higher speeds, significantly increasing production rates without sacrificing fabric quality. | Reduces energy consumption per meter of fabric produced. |

| Versatility | Can handle a wide variety of yarn types and fabric structures, including delicate fabrics. | Enables the use of recycled and eco-friendly yarns, minimizing waste. |

| Reduced Waste | Advanced technology reduces fabric defects and downtimes, leading to lower material waste. | Supports sustainability by maximizing material usage. |

| Cost-Effective | Lower production costs due to efficient operation and reduced waste. | Contributes to affordable sustainable fashion solutions. |

| Quality Control | Excellent fabric quality with minimal defects through precise control mechanisms. | Improves sustainability by producing longer-lasting fabrics. |

| User-Friendly Interface | Intuitive controls make it easy for operators to adjust settings and monitor processes. | Less need for retraining leads to efficient operations and lower environmental impact. |

| Energy Efficiency | Design promotes low energy consumption compared to traditional looms. | Helps in reducing carbon footprint associated with textile manufacturing. |

| Quick Changeover | Allows for rapid changeover between different styles and designs. | Reduces production time and increases flexibility in product offerings. |

| Innovative Technology | Incorporates state-of-the-art technology for improved functionality and performance. | Encourages the integration of smart systems for enhanced eco-friendliness. |

| Scalability | Easily scalable for small batches or large-scale production. | Promotes sustainable practices by matching production volume with demand. |

Related Posts

-

Top Benefits of Rapier Looms for Modern Textile Manufacturing

-

Top 10 Tips for Choosing the Right Textile Machine for Your Business

-

2026 Top Loom Machine Trends You Need to Know About

-

Ultimate Guide to Choosing the Best Yarn Twister for Your Knitting Projects

-

Top Benefits of Using a Cone Winding Machine for Efficient Yarn Production

-

Top 10 Benefits of Using a Wool Loom for Your Craft Projects