Complete Guide to Textile Manufacturing

A Step-by-Step Guide to Textile Production

Textile manufacturing is the heartbeat of fashion, home decor, and the industrial fabric industry. It’s a process that turns raw fiber into fabrics and eventually into products we use on a day to day basis – from clothing and upholstery to medical and technical textile.

For business and entrepreneurs, understanding how textile manufacturing works and how innovations in textile machine manufacturing are shaping the future can open doors to new opportunities in this globally competitive industry.

What is textile manufacturing?

At its core, textile manufacturing is the transformation of raw fabrics, either like natural wool, cotton, and silk, or synthetic materials like polyester, nylon, and acrylic, into finished textile products. The process typically follows these stages:

- Fiber Sourcing – Selecting the right raw material is crucial for quality and feel for the final product. Cotton remains the most widely used natural fiber, while polyester leads in synthetic production.

- Yarn Production – Fibers are cleaned, carded, combed, and spun into yarns using advanced spinning machines.

- Fabric formation – Yarns are converted into fabrics through weaving, knitting, nonwoven processes, braiding, felting, bonding or spread tow methods.

- Wet Processing and finishing – Fabrics undergo treatments, such as sourcing, bleaching, dyeing, printing, and functional finishing.

- Product manufacturing – Finished fabrics are cut, stitched, and packaged into garments, home furnishings, or industrial textiles.

Different Types of Textile Production

Textile manufacturing methods vary depending on the desired end use :

- Weaving – Interlacing warp and weft yarns on a loom to create strong, stable fabrics

- Knitting – Forming loops from yarn to produce flexible, stretchable fabric

- Braiding – Crossing yarns for ropes, cords, and decorative trims

- Felting – Compressing fibers into dense, nonwoven fabric without spinning or weaving

- Bonding – Using heat adhesives or pressure to fuse fibers into fabric sheets

- Spread Tow – Aligning fiber into flat tapes before weaving, often for composites

Each technique has unique advantages, and modern textile machine manufacturing ensures these processes are faster, precise and more sustainable.

Production Planning & Efficiency

Efficient textile manufacturing isn’t just about the machines, but it’s about planning, production to minimise the waste and maximise output:

- Batch production – Ideal for smaller runs and seasonal collections; offers flexibility but can require more setup time.

- Continuous Production – Best for high volume operations, reduces downtime, and increases consistency.

An optimised production line, supported by advanced textile machinery, can cut lead times by up to 50 % and reduce fabric waste up to 15-20%.

Emerging and Current Market Trends in Textile Manufacturing

Eco-Friendly Procedures and Sustainability

Bamboo, organic cotton, and recycled polyester fabrics are becoming more and more popular. Eco-friendly methods like low-impact dyeing and enzyme-based bio-polishing are becoming commonplace in the sector.

The market for sustainable textiles is expected to grow at a compound annual growth rate (CAGR) of 8.4% between 2023 and 2030.

Automation and Smart Technologies

3D knitting, IoT-enabled devices, and AI-powered looms are assisting producers in increasing accuracy while lowering labor expenses and errors.

By 2027, automation may reduce production costs by as much as 30%.

3D Textiles and Their Technical Uses

Advanced textiles for use in automotive, medical, and aerospace applications are being made possible by advancements in 3D knitting, weaving, and textile-based 3D printing.

The technical textiles market is expected to grow from USD 212 billion in 2022 to USD 318 billion by 2032.

Useful Finishes

Performance textiles are increasingly being treated with anti-static, antimicrobial, flame-retardant, and water-repellent finishes.

In 2021, functional finishing agents—such as water repellents—accounted for more than 88% of global textile finishing revenue, with the water-repellent segment making a substantial contribution.

On-Demand and Digital Fabric Printing

Short-run, customizable designs with less of an impact on the environment are made possible by digital printing technologies.

At a compound annual growth rate (CAGR) of about 12.4%, the digital textile printing market is expected to reach USD 18.22 billion by 2034 from USD 5.66 billion in 2024.

How it affects the Entrepreneurs

For textile and textile manufacturers alike, understanding this ecosystem helps you :

- Choose the right production for your market niche.

- Identify opportunities for innovation – like smart manufacturing or eco-friendly finishes.

- Plan production intelligently – balancing batch production flexibility with scale and efficiency flow.

- Stay competitive by investing in emerging technologies like digital printing or 3D textiles.

The role of textile machine manufacturing

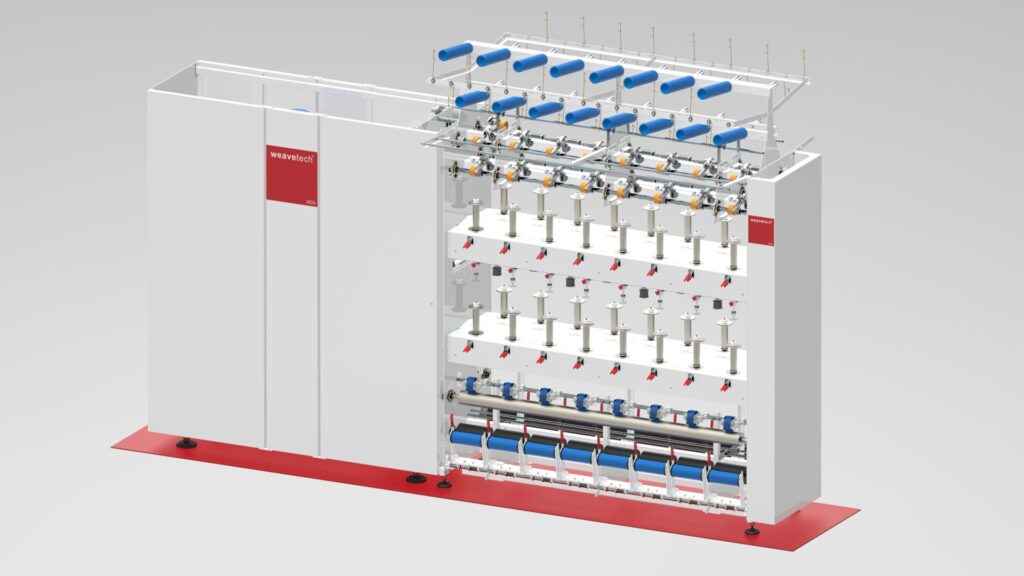

Behind every high-quality fabric lies sophisticated machinery. From spinning frames and weaving looms to knitting machines and digital printers, textile machine manufacturing is the backbone of the industry’s evolution.

Today’s Machines are designed for

- Higher production speeds without compromising quality.

- Energy efficiency and lower environmental impact.

- Integration with software for data-driven production planning.

Manufacturers investing in modern machinery gain a competitive edge, reduce downtime, and improve product consistency.

Concluding takeaway

Textile manufacturing is a centuries-old craft and a modern industry. It combines traditional methods with modern equipment and eco-friendly practices. This industry offers many opportunities for business owners, suppliers, and investors, especially when paired with the latest innovations in sustainable technology and textile machine production.

Knowing each step of the process—from sourcing fiber to finishing—and keeping an eye on market trends will help your company succeed and expand quickly on a global scale. Technology, sustainability, and smart strategy all come together in the textile manufacturing sector, whether you are producing luxury fabrics, industrial materials, or everyday clothing.

Related Reading: Types of Textile Machinery Used in Textile Industries